Innovation

Maken Kiosk has a strong R&D team with over 30 experienced designers & engineers who have the intelligence and understanding to create the state-of the-art design and construction.

We serve global customers, paying attention to the personalized needs and usage feedback of customers in different industries, and continuously optimizing our product design and manufacturing processes based on effective suggestions.

We also strictly control the innovation from all the segments of production, quality control, business model, finance, etc. which are the key factors to maintain competitive advantages.

Team Work

Sales, designers, engineers, quality controllers, logistics staff and others involve in a team. Under a clear division of labour, we respect the professionalism and individuality of each member. We openly share our goal and action plans to ensure that everyone understands their roles and how their work will affect the team.

We encourage everyone to face problems and challenges directly, actively participate, discuss issues, utilize their unique skills and work as a part of the team. Finally the strong teamwork power makes us to provide the best products, solutions and services to our customers.

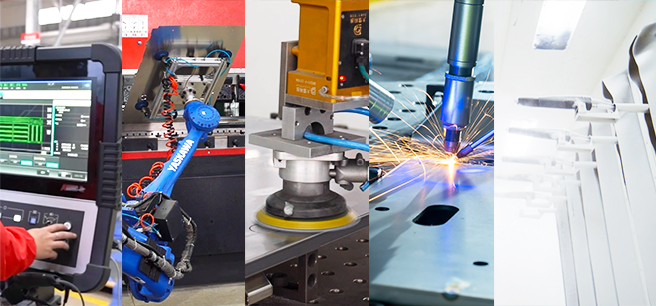

We are also proud of working with the global partners to achieve success together.Comprehensive Manufacturing Capacities

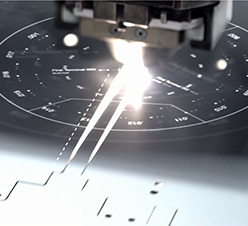

• Advanced laser cutting, turret punching and bending equipment for sheet metal fabrication and prototyping;

• Advanced machining and CNC Equipment for mold building;

• Advanced plastic tooling and injection machines for plastic production;

• Various stamping machines for progressive dies production;

• Full production equipment lines to support metal works secondary processes;

• Flexible assembly lines for smart production plan.

Flexible Custom

Based on our excellent development capabilities, extensive customer cases we served, and years of project experience, we are confident in responding to various of customization needs. We provide a wide range of custom design options and full service from concept to real products.

We help customers to design unique products to stand out from market competition, achieve higher benefits and brand awareness.

Cutting

AMADA High speed fiber laser cutting

AMADA NC Punching machine

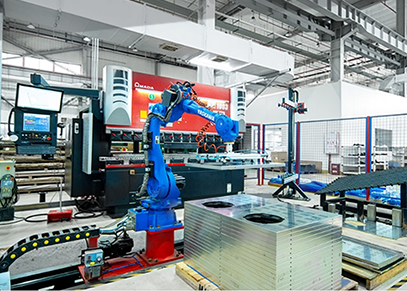

Bending

AMADA NC Bending machine

AMADA Robot auto bending machine

Stamping

Stamping workshop

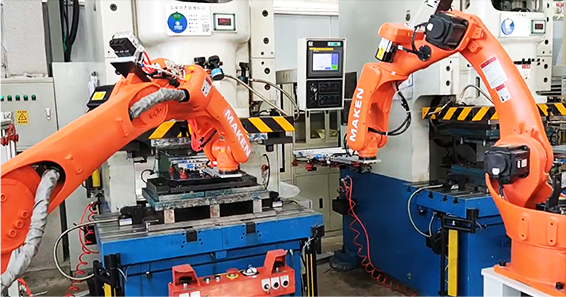

Robot auto stamping machine

Weldings

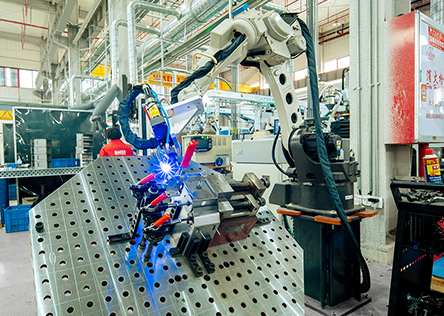

Robot fiber welding machine

Robot pulse welding machine

TIG welding

Resistance welding line

Secondary Processes

Robot auto-polishing machine

Manual grinding platform

Auto de-burring & grinding machine

Riveting machine

Powder coating

Powder coating line

Assembly

Electornic assembly - dust-free shop

Regular assembly line

Mold making and machining

HAAS Y-axis NC milling machine

HAAS super-speed NC latch machine

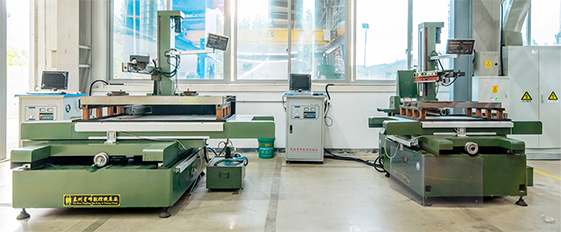

Sodick NC-EDM wire-cutting machine

Grinding machine

Fast NC-EDM wire-cutting machine

EDM Cutting machine

Inspection

Packing

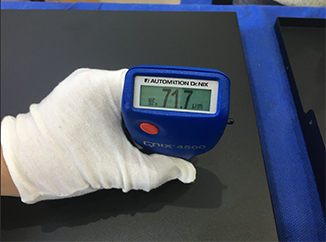

Maken performs Total Quality Management. TQM strictly controls the whole process from product development to manufacturing. The laboratory has a complete set of life and quality testing equipments.

IQC / PQC / OQC

Product usage

Customer feedback

Market feedback

Process tech.

Maken streamlines a detailed time schedule for each project to promote the project from initial concept to realization of product. The whole procedures conforms to ISO 9001:2015 quality management standard.

The Project management will comprehensively commit to project schedule from customers at time and budget, resource utilization, and greatly collaborate with customers to push forward the products to the market at low risk and cost efficiency.

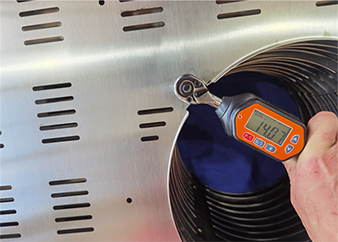

We have independent laboratory with full facility for product life and quality test.

Inspection

Maken industrial plant has an independent laboratory with full facility for product life and quality test.